Pipe with fixed diameter of 300 is generally welded for several times of spot welding or continuous welding. To be specific, in a pipe with a diameter of one meter, it is generally welded for several times of spot welding or even welding how to welding

1. Generally, 3.2 welding rod is used for welding 300 pipes, and it is welded twice.

2. Reasonable current selection;The current should not be too large, too large current is easy to splash, bite edge, droop welding.Also can not be too small, the current is too small welding, slag, affect quality, appearance will not be flat.

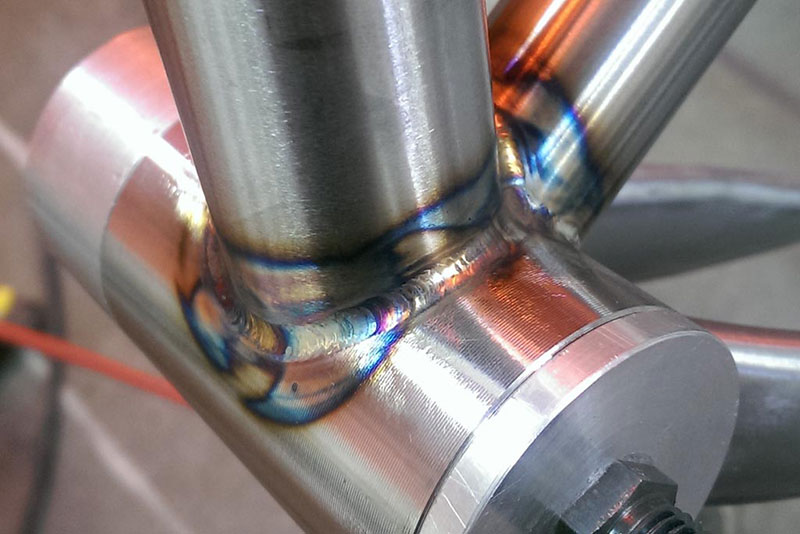

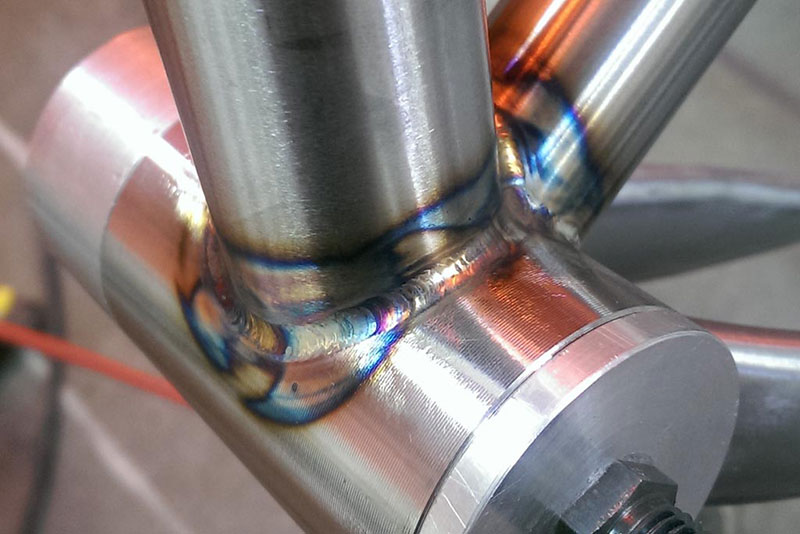

3, the pipe welding 300 must do single-side welding and double-sided molding, to make a good groove, the gap between the mouth must be uniform, the size of a welding rod diameter, welding to watch the molten iron, listen to the good voice, hear the "puff" penetration sound to ensure that the inside is very good molding.

4. Bake the electrode for 1 hour at 150° before use, and put it in the insulation bucket for use at any time.Windscreen should be installed when the wind is strong outside.

5, electric welding 300 pipe welding generally two times, before the second time of welding, clean the welding mouth, pay attention to the shape of the welding pool, watch both sides of the base material can not bite edge, pay attention to ensure the height of welding seam, pay attention to the quality of welding rod joint.

Silver-Copper-Zinc-Cadmium Brazing Alloy

sales@welding-material.com

sales@welding-material.com