Aluminum base metals present a number of challenges during brazing. First, the low melting temperature of aluminum base metals requires more precise heat control, and the lack of color change that occurs during heating doesn’t give braze operators any visual indication that the base metal has reached the proper brazing temperature.

Second, many of the challenges associated with aluminum brazing are related to heat transfer. Manufacturers do not want premature melting of brazing alloy (most often in ring form) or localized areas of heat that create “hot spots”. Heating must be even across the base metals and the ring, and the flux must be activated in advance of the ring melting. Even heat transfer ultimately makes processing success easier to achieve in difficult applications like 3 and 4-row coils.

Last, because aluminum forms a tough oxide during brazing, the use of flux is essential. Fluxing can add an entirely new step to the brazing process and can affect the appearance of the finished braze product. Depending upon the type of flux used (corrosive v. non- corrosive), an additional step may be required if the flux residue must be removed after brazing. Flux is available in a variety of forms including paste, slurry, powder, and “combined” forms.

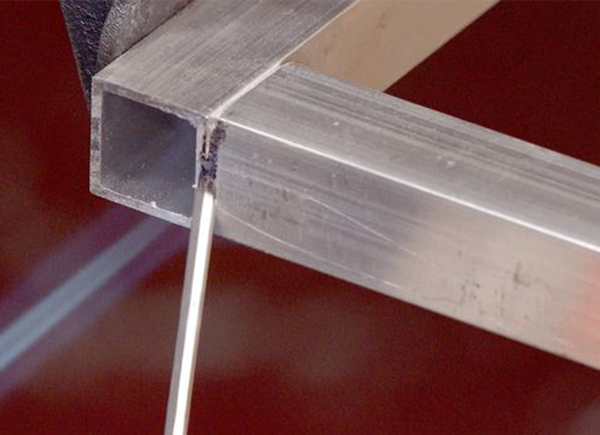

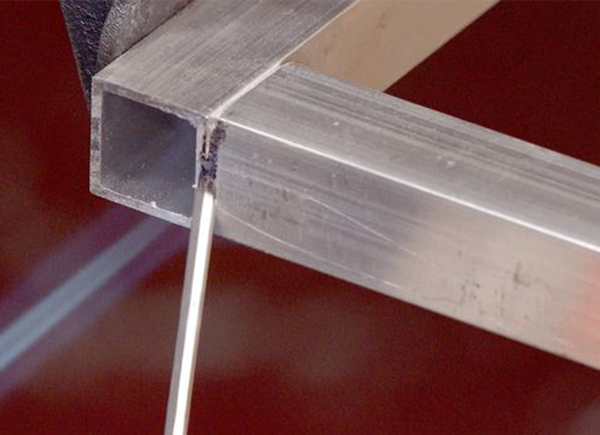

Aluminum base brazing alloys is mainly used for brazing aluminum with aluminum alloy. The brazing aluminum with aluminum alloy use Al-SI Flux-cored wire to substitute ordinary ER4047 wire, with corrosive flux inside, easy to welding. It is particularly suitable for brazing aluminum parts in refrigeration, air-condition and automotive industry.

Copper-Aluminum flux-cored wire is an innovation environmental brazing material especially designed for electrical component. It can easily achieve the brazing of copper row with aluminum row, copper wire with aluminum wire. Brazing alloy composition meets ROHS directive. The powder in the wire center is the flux impacting on brazing alloy’s fluidity in Copper-Aluminum base metal, is a combination from different kinds of fluoride, non corrosive and very stable in normal atmosphere, so it can be kept in stock for long time without problem. For components with special brazing joints(big surface or different shape), we can provide alloy in wire or sheet form, matched with suitable flux in paste, which will be an easy solution for operators. It’s suitable for brazing copper with aluminum, aluminum with aluminum, aluminum with steel, aluminum with stainless steels, etc.

sales@welding-material.com

sales@welding-material.com