Welding and brazing both use heat. They both use filler metals. They can both be performed on a production basis. But the resemblance ends there. They work differently, and you need to understand the nature of that difference to know which method to use where.

HOW WELDING WORKS

Welding joins metals by melting and fusing them together, usually with the addition of a welding filler metal. The joints produced are strong, usually as strong as the metals joined or even stronger.

In order to fuse the metals, a concentrated heat is applied directly to the joint area. This heat is high temperature.

It must be—in order to melt the “base” metals (the metals being joined) and the filler metals as well. So welding temperatures start at the melting point of the base metals.

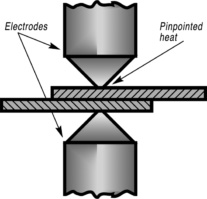

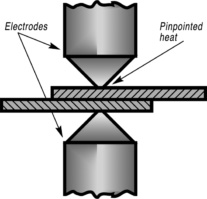

Because welding heat is intense, it is impractical to apply it uniformly over a broad area. Welding heat is typically localized, pinpointed heat. This has its advantages. For example, if you want to join two small strips of metal at a single point, an electrical resistance welding setup is very practical.

This is a fast, economical way to make strong, permanent joints by the hundreds and thousands.

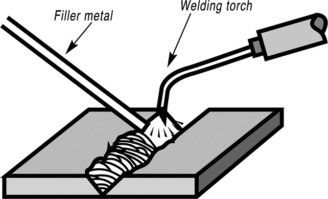

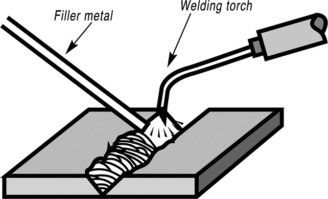

However, if the joint is linear, rather than pinpointed, problems arise. The localized heat of welding tends to become a disadvantage. For example, suppose you want to butt-weld two pieces of metal—start by beveling the edges of the metal pieces to allow room for the welding filler metal. Then weld, first heating one end of the joint area to melting temperature, then slowly traveling the heat along the joint line, depositing filler metal in synchronization with the heat.

This is a typical conventional welding operation. Let’s look at its characteristics.

It offers one big plus—strength. Properly made, the welded joint is at least as strong as the metals joined.

But there are minuses to consider.

The joint is made at high temperatures, high enough to melt both base metals and filler metal. High temperatures can cause problems, such as possible distortion and warping of the base metals or stresses around the weld area.

These dangers are minimal when the metals being joined are thick. But they may become problems when the base metals are thin sections.

High temperatures are expensive as well since heat is energy, and energy costs money. The more heat you need to make the joint, the more the joint will cost to produce.

Now consider the automated process. What happens when you join not one assembly, but hundreds or thousands of assemblies? Welding, by its nature, presents problems in automation. We know that a resistance weld joint made at a single point is relatively easy to automate. But once the point becomes a line—a linear joint—the line has to be traced. It’s possible to automate this tracing operation, moving the joint line, for example, past a heating station and feeding filler wire automatically from big spools. But this is a complex and exacting setup, warranted only when you have large production runs of identical parts.

Of course, welding techniques continually improve. You can weld on a production basis by electron beam, capacitor discharge, friction and other methods. But these sophisticated processes usually call for specialized and expensive equipment and complex, time-consuming setups. They’re seldom practical for shorter production runs, changes in assembly configuration or—in short—typical day-to-day metal joining requirements.

sales@welding-material.com

sales@welding-material.com